Stainless Steel Pipe AISI ASTM A249 Ss 201 304 304L 316 316L Seamless Inox Stainless Steel Tube for Boiler Heat Exchanger Tube 316L Stainless Steel Pipe

Overview ASTM A240 201 202 304 304L 316 316L 1.5-50mm Thickness Mirror 2B Finish Stainless Steel Square Round Pipe 316L

Send your inquiryDESCRIPTION

OverviewBasic Info.

| Model NO. | BY-SS-T38 |

| Surface Treatment | Polished |

| Wall Thickness | 1mm-150mm |

| Capacity | 20000 Tons Per Year |

| MOQ | 1t |

| Od | 6mm-2500mm |

| Length | 12m, 6m, 5.8m, 3m |

| Transport Package | Sea Shipping Packs |

| Specification | Customized |

| Trademark | Bangying |

| Origin | China |

Product Description

ASTM A240 201 202 304 304L 316 316L 1.5-50mm Thickness Mirror 2B Finish Stainless Steel Square Round Pipe316L Stainless Steel Pipe by Bangying

China Stainless Steel Pipe AISI ASTM A249 Ss 201 304 304L 316 316L Welded Seamless Inox Stainless Steel Tube for Boiler / Heat Exchanger Tubes

Stainless Steel Pipe AISI ASTM A249 Ss 201 304 304L 316 316L Welded Seamless Inox Stainless Steel Tube for Boiler

Product Description

SMLS Stainless Steel Tube /Pipe

| Itme | Surface finishing | Surface finishing methods | Main application |

| NO.1 | HR | Heat treatment after hot rolling, pickling, or with treatment | For without the purpose of the surface gloss |

| NO.2D | Without the SPM | Method of heat treatment after cold rolling, pickling surface roller with wool or eventually a light rolling a matte surface processing | General materials,building materials. |

| NO.2B | After SPM | Giving No.2 processing materials appropriate method of cold light sheen | General materials, building materials ( most of the goods are processed ) |

| BA | Bright annealed | Bright heat treatment after cold rolling , in order to be more shiny, cold light effect | Automotive parts, home appliances, vehicles, medical equipment, food equipment |

| NO.3 | Shiny, coarse grain processing | The NO.2D or NO.2B processing timber No. 100-120 polishing abrasive grinding belt | Building materials, kitchen supplies |

| NO.4 | After CPL | The NO.2D or NO.2B processing timber No. 150-180 polishing abrasive grinding belt | Building materials, kitchen supplies, vehicles, medical equipment, food equipment |

| 240# | Grinding of fine lines | The NO.2D or NO.2B processing timber 240 polishing abrasive grinding belt | Kitchen appliances |

| 320# | More than 240 lines of grinding | The NO.2D or NO.2B processing timber 320 polishing abrasive grinding belt | Kitchen appliances |

| 400# | Close to BA luster | The MO.2B timber 400 polishing wheel polishing method | Building materials, kitchen utensils |

| HL (hair lines) | Polishing line having a long continuous processing | In a suitable size ( usually mostly No. 150-240 grit ) abrasive tape for as long as the hair, having a continuous processing method of polishing line | The most common building materials processing |

| NO.6 | NO.4 processing less than the reflection , the extinction | NO.4 processing material used for polishing Tampico brushing | Building materials, decorative |

| NO.7 | Highly accurate reflectance mirror processing | No. 600 of the rotary buff with a polishing | Building materials, decorative |

| NO.8 | Highest reflectivity mirror finish | Fine particles of abrasive material in order polishing , mirror polishing with a polishing | Building materials, decorative, mirrors |

2. OD: 1/8"-100" (6-2500mm)

3. WT: SCH10-SCHXXS (1-150mm)

4. Length: 5.8m, 6m, or as required

5. Package: Bundles, seaworthy wooden (Plywood) boxes or according to customers' requirements.

6. Application

A) General service industries (petroleum\military \food\ chemical\paper\ fertilizer\fabric\aviation and nuclear)

B) Fluid, gas and oil transport

C) Pressure and heat transmission

D) Boiler\pressure vessel\heat exchanger and condenser.

stainless steel welded pipe/tube:

| Material Grade | 304,304L,309S,310S,316,316Ti,317,317L,321,347,347H,304N,316L, 316N,201,202 |

| Standard | JIS/JIS/SUS/GB/DIN/ASTM/AISI/EN |

| Surface | Polishing,annealing,pickling,bright |

| Technique | Cold Rolled; Hot Rolled |

| Size | 1)stainless steel round pipe/tube: Wall thickness:1mm-150mmOuter diameter:6mm-2500mm2)stainless steel square pipe/tube:Wall thickness:1mm-150mmOuter diameter:4mm*4mm-800mm*800mm3)stainless steel rectangular pipe/tube: Wall thickness:1mm-150mmOuter diameter:6mm-2500mm |

| Length | 4000mm,5800mm,6000mm,12000mm,or as required. |

| Applicaiton | Exterior decoration; Architectur; Evevator; Kitchen; Ceiling; Cabinet; Advertising nameplate; Roof structure;Shipbuilding |

| Trade Terms | EXW,FOB,CIF, CFR |

| Loading Port | Shanghai port, Tianjin port, Qindao port, etc. |

| Payment terms | 1) T/T 30 % deposit in advance and balance 70%T/T before delivery. |

| 2) 30% deposit by T/T, the balance by L/C at sight. | |

| 3) 100% L/C at sight. | |

| MOQ | 1Ton |

| Packing Detail | Plastic bag/woven packing or per requirements |

| Delivery time | 1.Usually,within10-20days after receiving deposit or LC.2.According to the order quantity |

| Samples | Free samples are provided but the freight is borne by the buyer |

Certifications

Our Advantages

Packaging & Shipping

FAQ

Q1: Can you send samples?

A:Of course, we can provide customers with free samples and express shipping service to all over of the world.

Q2: What product information do I need to provide?

A:Please kindly provide the grade, width, thickness, surface treatment requirements, and the quantity to order.

Q3: It's my first time to import steel products, can you help me with it?

A:Sure, we have the shipping agent to arrange the shipment, and we will work together.

Q4: What ports of shipment are there?

A:Under normal circumstances, we ship from Shanghai, Tianjin, Qingdao, Ningbo ports, you can specify other ports, according to your needs.

Q5: What about product prices information?

A:Prices varied, according to periodic price changes of raw materials.

Q6: What is your terms of payment ?

A:Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance, balance before shipment or based on BL copy or LC at sight.

Q7: Do you provide ODM services?

A: Yes, if you have your own design, we can produce according to your specification and drawing.

Q8: What are the certifications for your products?

A: ISO 9001, MTC, third parties' inspections such SGS, BV, ect. are available.

Q9: How long does your delivery time take?

A:In general, our delivery time is within 7-15 days, and may be longer if the quantity is extremely large or special circumstances occur.

Q10: How many countries you already exported to?

A:We have exported to America, Canada, Brazil, Chile, Colombia, Russia, Ukraine, Thailand, Myanmar, Vietnam, India, Kenya, Ghana, somalia and other African countries. Our export experience is rich, we familiar with different market demands, can help customers avoid a lot of trouble.

Q11: Can I go to your factory to visit?

A:Of course, we welcome customers from all over the world to visit our factory.

Q12:Does the product have quality inspection before loading?

A:Of course, all our products are strictly tested for quality before packaging, and unqualified products will be destroyed and customers can appoint the 3rd Parties to inspect the products before loading.

Related Products

-

![Stainless Steel Seamless Pipe (304H 304 316 316L 321 310S 410s)]()

Stainless Steel Seamless Pipe (304H 304 316 316L 321 310S 410s)

-

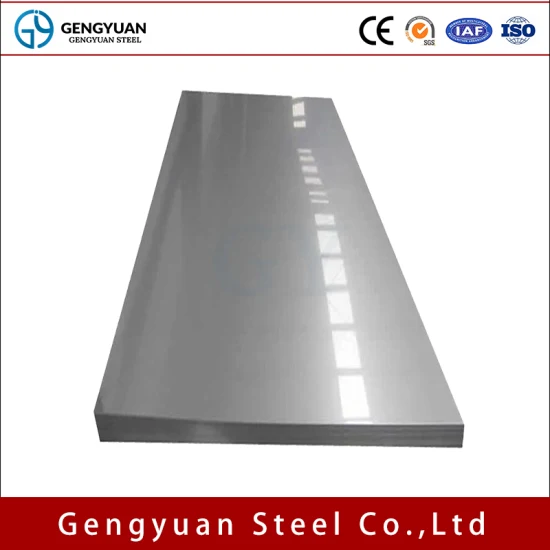

![SUS 201 304 316 317 403 410 429 430 601 630 2205 2507 254smo 2b Ba No. 1 No. 4 8K Duplex Hot/Cold Rolled Decorative Stainless Steel Sheet for Industry]()

SUS 201 304 316 317 403 410 429 430 601 630 2205 2507 254smo 2b Ba No. 1 No. 4 8K Duplex Hot/Cold Rolled Decorative Stainless Steel Sheet for Industry

-

![ISO SGS 304 316 430 904 2205 2507 2b/Ba/8K Mirror/Hairline/No. 4 Satin/Bead Blast/Color Etched Stainless Steel Sheet for Decorative]()

ISO SGS 304 316 430 904 2205 2507 2b/Ba/8K Mirror/Hairline/No. 4 Satin/Bead Blast/Color Etched Stainless Steel Sheet for Decorative

-

![304/430 5wl Mirror Stamping Stainless Steel Sheet 3D Design for Wall Panel]()

304/430 5wl Mirror Stamping Stainless Steel Sheet 3D Design for Wall Panel