Surface Electrophoretic Metal Cover Sheet for Surveillance Camera Precision Metal Stamping Parts

Surface electrophoretic metal cover sheet for surveillance camera precision metal stamping parts Product Description Sim

Send your inquiryDESCRIPTION

Basic Info.

| Model NO. | EL0198-00 |

| Fine Blanking | Double Acting |

| Process | Forming Process |

| Industry | Metal Stamping Parts |

| Tolerances | 0.05-0.10mm |

| Customized | Customized |

| Function | 48-Hours Salt Spray Test |

| Transport Package | Tray/Carton |

| Trademark | ELMAX |

| Origin | China |

| Production Capacity | 20000pieces/Day |

Product Description

Surface electrophoretic metal cover sheet for surveillance camera precision metal stamping parts| STAMPING EQUIPMENT | ||

| ITEM NAME | SPECIFICATION | QUANTITY(SET) |

| Taiwan Mingxu Precision high-speed punching machine | 25T | 1 |

| Taiwan Mingxu Precision high-speed punching machine | 45T | 2 |

| Taiwan SEYI Precision punching machine | 60T | 3 |

| Taiwan SEYI Precision punching machine | 80T | 1 |

| Taiwan CHINFONG Precision punching machine | 110T | 1 |

| Wangpan precision grinding machine | 2 | |

| Wangpan precision milling machine | 2 | |

| Marriott Precision 2.5 Dimensions | 2 | |

| Marriott Precision Projector | 2 | |

| TOTAL | 8 | |

Product Description

| Product Type | metal stamping, Multistep/single Progressive Dies |

| Material | SUS304, Phosphor bronze,copper, thickness: 0.2mm-0.4mm |

| Process Methods | Punching/Stamping/Bending stamping |

| Tolerance | In general:+/-0.05 mm, can be more precision,according to your requirement. |

| surface treatment | copper plating+nickel plating |

| Applications | Mainly used in optical fiber transceiver |

| Delivery time | For stamping ,20-25 working days(including surface finishment) ,Mass production: 2-3 weeks |

| Advantages | Good Quality with strict inspection process/Competitive Price and prompt delivery time |

Similar product

Company Profile

As a one-stop OEM/ODM service provider, ELMAX has always been committing to the technology of stamping and plastic injection molding ; Focusing on tooling and mass production of Stamping parts, Injection-molded plastic parts and Insert-molding components. The products range is inclusive of hardware stamping parts, metal stamping, sheet stamping,plastic injection parts used for security camera/ CCTV camera, optical transceiver and varies of relays. The main customers of ELMAX are domestic well-known companies and partners comes from all of the world especially from Europe/America, such as FINISA, PVS, Amphenol,TTI and so on.

Metal stamping workshop

Quality guiding principle

Quality is the lifeblood of an enterprise, and customers are forever mentors.

Management Philosophy

Related Products

-

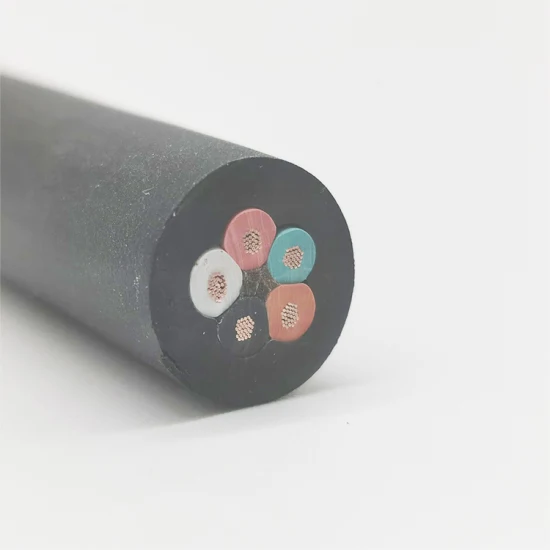

![Copper Aluminum Conductor Single 3 Core Underground Armoured Power Cable for 6/10kv 8.7/15kv 12/20kv 18/30kv]()

Copper Aluminum Conductor Single 3 Core Underground Armoured Power Cable for 6/10kv 8.7/15kv 12/20kv 18/30kv

-

![33kv PVC/XLPE/PE Insulated PVC Sheatd Aluminum Copper Under Armoured Medium Voltage Power Cable]()

33kv PVC/XLPE/PE Insulated PVC Sheatd Aluminum Copper Under Armoured Medium Voltage Power Cable

-

![Customized Pattern Grade 201 304 316 Mirror Etched Stainless Steel Sheet]()

Customized Pattern Grade 201 304 316 Mirror Etched Stainless Steel Sheet

-

![Aofu Wiremesh Perforated Skid Plate Factory Die Stamping Laser Cutting Stainless Steel Perforated Plate China Galvanized Sheet Punching Sheet]()

Aofu Wiremesh Perforated Skid Plate Factory Die Stamping Laser Cutting Stainless Steel Perforated Plate China Galvanized Sheet Punching Sheet